Mike Roig, Sculpture

On the Wing

A commissioned sculpture for Automation Direct

in Cumming, Ga.

Late January 2018

The last few weeks have been all about that base.

There are a lot of steps to making that deceptively simple looking form that will

attach securely to the pedestal and support the rotating shape above. Since it will be sitting on

that elegant pedestal, it was decided to go with an all stainless steel base to eliminate any rust bleeding

down its facade.

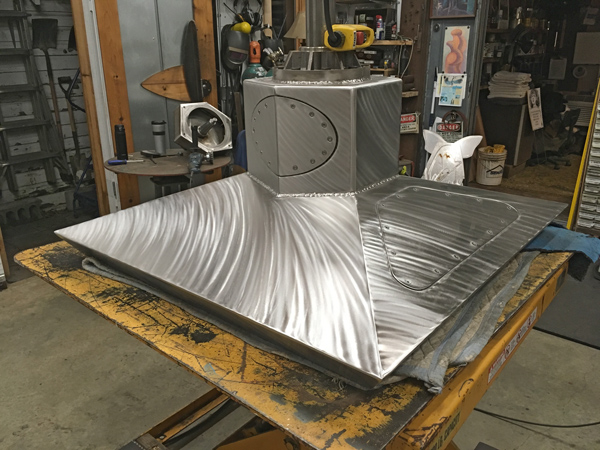

The hub that supports the axle and bearings has eight lug bolts which required

drilling in the plate that would form the top of the base. You can see the plate and hub sitting on the yellow work

table. In the foreground is the first plate with the eight anchor bolt holes that will eventually

secure the sculpture to the pedestal.

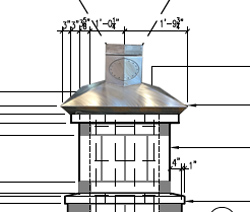

I like the proportions Jim drew in his rendering of the pedestal, and so the height of the sides

was determined so as to maintain that ratio.

As you can see from the photo below of the underbelly of the maquette's kinetic element,

it is hexagonal at its lowest point, and this is what led to the base column adopting the hexagonal form.

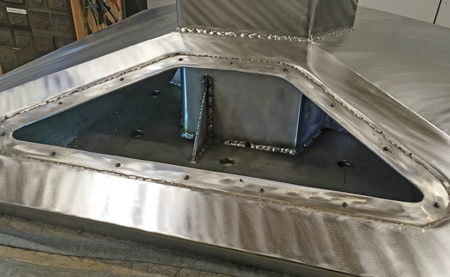

After an initial sanding of the welded seams, the next step was creating an access door

into the base to be able to install the lower bearing and retaining nut on the three-inch axle.

The concrete core of the pedestal is slightly over 2' x 2', and that first plate conforms to that dimension.

The second, larger plate is 37.5 inches square, the dimension of the cast stone cap of the

pedestal. Together they make for a half-inch of steel through which the anchor bolts will pass to lock

down the sculpture.

In the picture above several steps have been accomplished. The hexagon has been welded to the

base plates and the first part of the skirting has been tacked to the larger base plate. Unseen from the outside,

triangular buttressing has been added inside the hexagonal column, further locking the plate supporting

the axle assembly to the sides.

Similar buttresses will be added at the hexagon's base adding addition rigidity

to it's attachment to the base plates. Another hexagonal box has been fabricated and welded to the axle allowing it to spin

with just the right clearance above its support. It is from this that the winged form will grow in the later

phases of the fabrication.

Next step, carefully create cardboard patterns for the precise fit of each of the four sides of the

shallow pyramid of the base, and then cut them out of 10 gauge steel.

Of course that's a little more complex, further complicated by the fact that there will need to be a way

into this part of the base in order to get the nuts onto those anchor bolts.

Welded, then edges sanded, and finally surface sanded below. There are two doors on opposite sides of the skirting

which allow ready access to all the anchor bolts.

I've created a pattern in luan paneling which will allow for precise placement of the anchors in the

pedestal concrete core.

I believe that makes a base, and a good place for a pause. I'll be working on a couple of other projects for a bit.

There will be a longer gap between this and the next update than there was in these first two.

But it's nice to have this much in non-virtual form.

©2018 Mike Roig, All Rights Reserved